FMEA

What is a FMEA

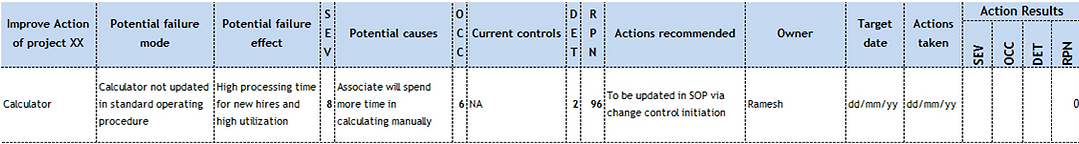

Expanded as Failure Mode Effect Analysis

It is a risk management tool - starts with a review of the process for failure modes (what could go wrong), then their effects, then causes of the failure modes. It also takes in to account the current controls in place to prevent failure.

The severity of failure effect; occurrence frequency of causes and ability to detect (of the current controls) are all rated and multiplied to produce an RPN -risk priority number; which once sorted in descending order can tell the high priority risk areas.

How to do FMEA

-

Gather the doers, explain the process

-

If you haven't done FMEA before, you may want to get experts to help

-

FMEA won't get done in a single sitting - so its ideal to gather the team for each step (or some steps together)

-

Between steps, you and /or a team member can work on the file to clean / update based on the last meeting and procure data as required

-

This is best done in an excel file

-

Step 1: PROCESS STEPS - write the major process steps or these could be changes you are planning to do

-

Step 2: FAILURE MODES - Against each Process step, list ways in which it can go wrong.

-

There would be multiple ways, so keep adding rows

-

You don't need to weed out now

-

Do spend time on each process step, ask questions - "what else", "how has it failed in the past".....

-

-

Step 3: FAILURE EFFECTS- List the various ways in which the failure modes would impact the customer

-

Step 4: CAUSES - List the causes of why the failure may happen

-

Step 5: CURRENT CONTROLS - List the current controls available to prevent/detect the failure

-

Now we do the ratings. Please check if your organization has a rating scale table for FMEA, which you can use for rating.

-

This will ensure that your stakeholders can relate to ratings

-

If your organization doesn't have one, see if you can google one for your use and before that confirm with an expert if possible

-

Step 6: PRODUCE RPN

-

Severity Rating - How severe is the impact of Effects; Low-1 to High-10

-

Occurrence Rating - How frequently do the Causes occur; Low-1 to High-10

-

Detection Rating - How effective is the Control in detecting/ preventing the failure; Low-10 to High-1

-

Calculate RPN = Severity * Occurrence * Detection ratings

-

RPN would range from 1 (1*1*1) to 1000 (10*10*10)

-

Sort in Descending order as per RPN

-

Check for consensus, make changes if necessary

-

You now have current state FMEA

When to use FMEA

-

To identify ways and methods in which a product or process or solution can fail

-

FMEA may be used to choose areas where projects need to done

-

At the start of a project to determine risk areas

-

At the start of the implementation of an improvement project

-

FMEA as an exercise can be used to reduce failure modes in a process

Improving from current state - RPN

-

Post sorting the current state FMEA - RPN in descending order you now know your biggest risk areas

-

Check with your organisation for a risk threshold RPN

-

Lets take that as 100, so any mode above RPN 100, needs to be controlled

-

STEP 7 : For each mode above threshold, review

-

The causes - can you get to the root cause ? ; can you reduce the frequency of occurrence, if not eliminate

-

The controls - can you increase the effectiveness of controls eg if the current control for people jumping off a 1 mile long bridge was , a police man patrolling - you can put very high barricades, that have spikes to dissuade people from climbing and jumping off.

-

Do note that we wont be able to impact severity - if someone jumps - it may be fatal, so severity remains 10 , however occurrence can be reduced by improving controls

-

Once you have reviewed and determined actions, now implement them with tracking and update the RPNs .

-

This review can throw up many projects to reduce RPNs.